2019 High quality Thread Steel Bar - 50mm Pt Bar – Cathay Detail:

50mm Pt Bar

Grade Number of Post Tensioning Tie Bars

| Grade | Yield Strength | Tensile Strength |

| 500 | 500MPa | 630MPa |

| 830 | 830MPa | 1030MPa |

| 930 | 930MPa | 1080MPa |

| 1080 | 1080MPa | 1230MPa |

Application of Post Tensioning System Bar,

Our Prestressing thread bar system Grade 930/1080 had been used on several bridges in India,Thailand and Colombia

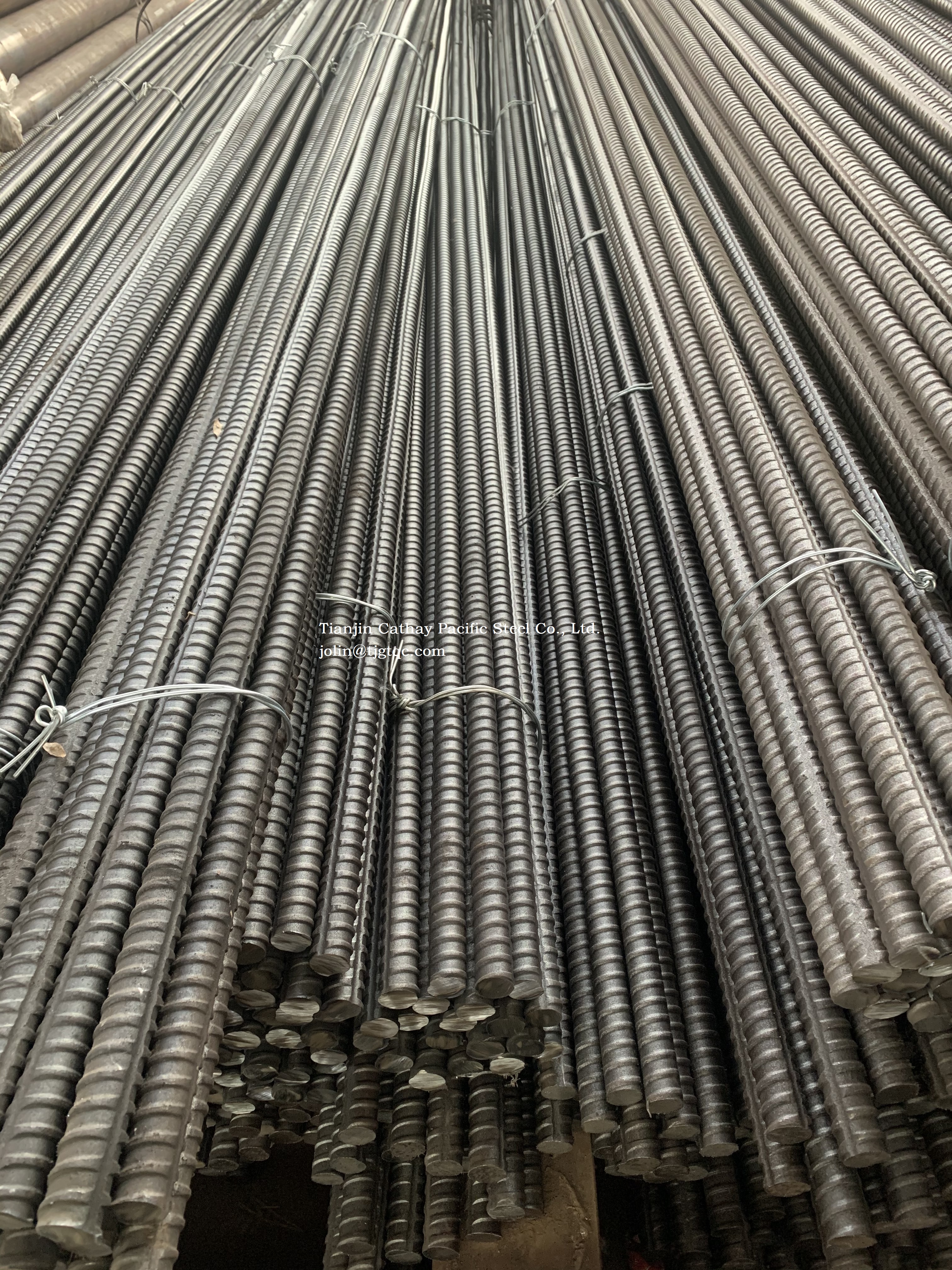

Stock for Post Tensioning Screw Thread Steel Bar

Lead time can be within 7 days.

Tianjin Guotai Gancheng Steel Co., LTD. Main business: fine rolled rebar and supporting anchor (fine rolled nut, fine rolled gasket, fine rolled connector, screw bar), 15.2 steel strand and other steel.

Introduce: Long term supply of Φ15, Φ20, Φ25, Φ28, Φ32, Φ36, Φ40, Φ42, Φ50, Φ63.5, Φ75 (mm) fine rolled screw steel.

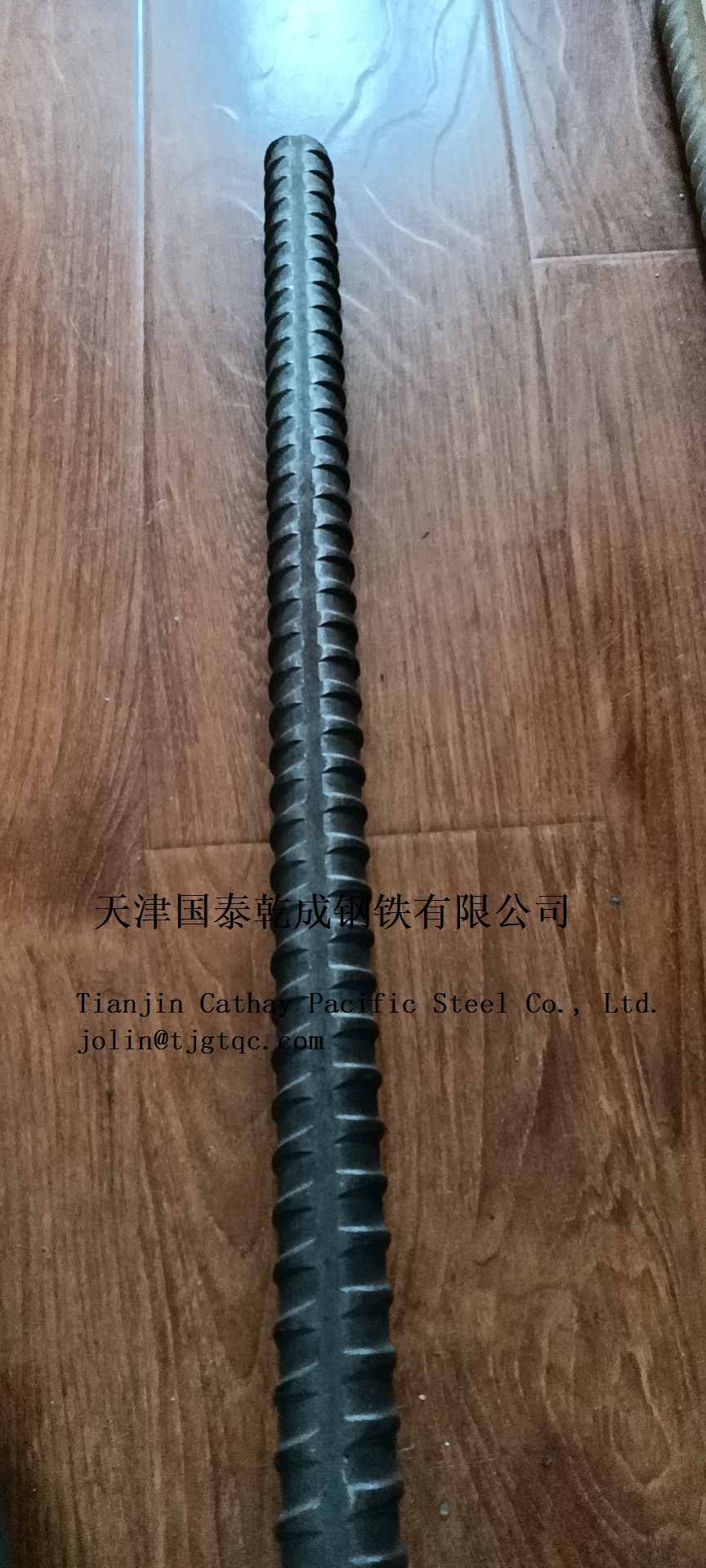

The threaded bar for prestressed concrete (also called fine rolled threaded bar) is a straight bar with large diameter, high strength and high dimensional precision rolled on the whole bar with discontinuous external thread. The steel bar at any section can be screwed on a connector with internal thread for connection or screwed on threaded nuts for anchorage.

Product detail pictures:

Related Product Guide:

Our primary purpose is to give our shoppers a serious and responsible company relationship, giving personalized attention to all of them for 2019 High quality Thread Steel Bar - 50mm Pt Bar – Cathay, The product will supply to all over the world, such as: Finland, Qatar, Nigeria, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

| Nominal Diameter | Diameter | H | B | L | Nominal Section | Nominal Weight | |

| Dv | Dh | ||||||

| mm | mm | mm | mm | mm | mm | mm2 | kg/m |

| 15 | 15 | 15 | 1.0 | 4.5 | 10 | 176 | 1.47 |

| 18 | 18 | 18 | 1.0 | 4.0 | 10 | 254.5 | 2.11 |

| 20 | 20 | 20 | 1.3 | 4.8 | 10 | 314 | 2.47 |

| 25 | 25 | 25 | 1.6 | 6.0 | 12 | 490.9 | 4.10 |

| 32 | 32 | 32 | 2.0 | 7.0 | 16 | 804.2 | 6.65 |

| 36 | 36 | 36 | 2.5 | 8.0 | 18 | 1018 | 8.41 |

| 40 | 40 | 40 | 3.0 | 8.0 | 20 | 1256.6 | 10.34 |

| 50 | 50 | 50 | 3.0 | 9.0 | 24 | 1963.5 | 16.28 |

| 60 | 60 | 60 | 3.0 | 10.0 | 22 | 2827 | 23.26 |

| 63.5 | 63 | 63.5 | 3.0 | 12.0 | 22 | 3167 | 26.20 |

| 65 | 65 | 65 | 3.0 | 12.0 | 22 | 3318 | 27.470 |

| 70 | 70 | 70 | 3.0 | 12.0 | 22 | 3848 | 31.8 |

| 75 | 75 | 75 | 3.0 | 12.0 | 22 | 4418 | 36.9 |

| Grade500/630 | NominalDia. | CrossSection | YieldStrength | TensileStrength | YieldLoad | UltimateLoad | Elongation | NominalWeight |

| mm | mm2 | >=Mpa | >=Mpa | KN | KN | A/% | KG/m | |

| 20 | 314 | 500 | 630 | 157 | 198 | 10 | 2.47 | |

| 25 | 491 | 500 | 630 | 246 | 309 | 10 | 4.1 | |

| 28 | 615 | 500 | 630 | 308 | 387 | 10 | 4.83 |

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.