OEM Manufacturer Hot Rolled Bar - Post Tensioning Screw Thread Steel Bar – Cathay Detail:

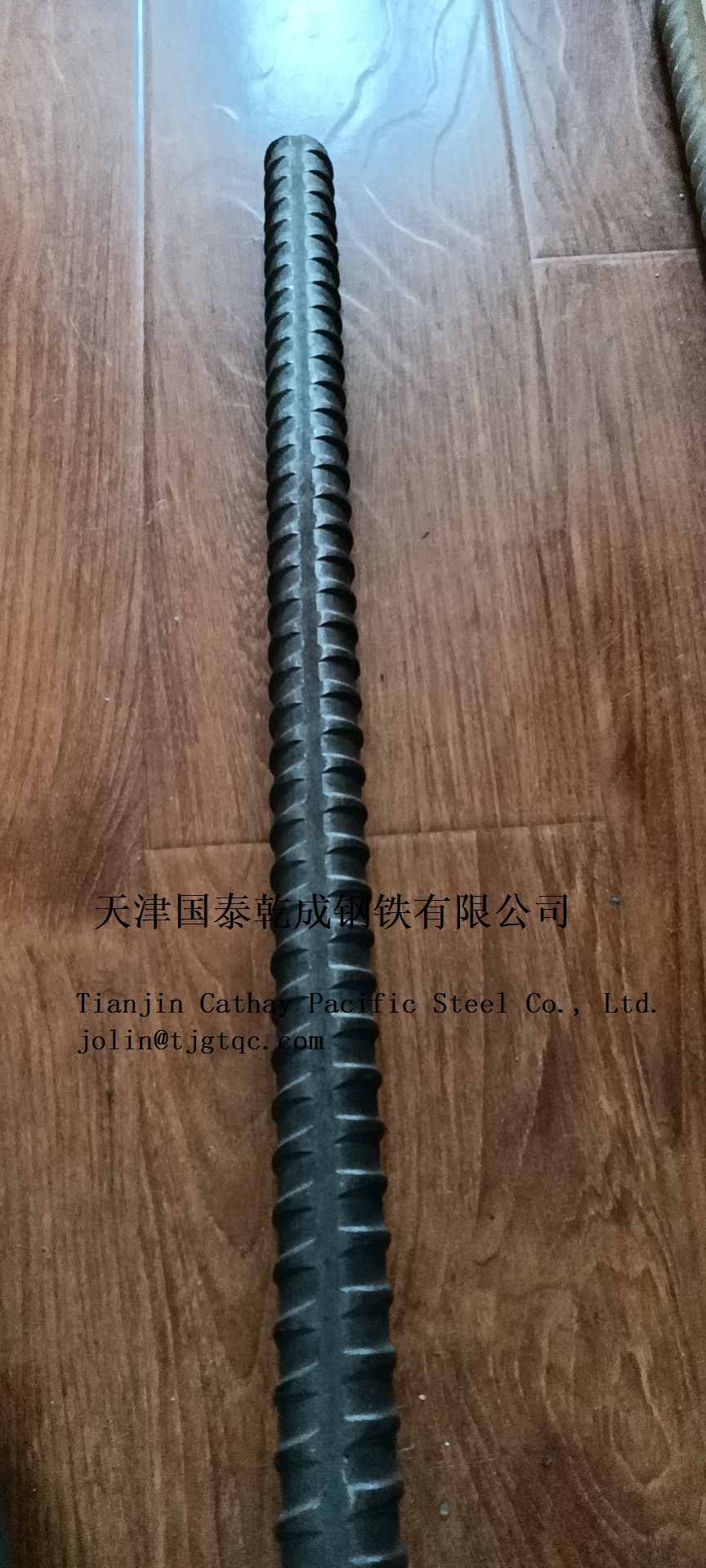

Post Tensioning Screw Thread Steel Bar

Grade Number of Post Tensioning Tie Bars

| Grade | Yield Strength | Tensile Strength |

| 500 | 500MPa | 630MPa |

| 830 | 830MPa | 1030MPa |

| 930 | 930MPa | 1080MPa |

| 1080 | 1080MPa | 1230MPa |

Application of Post Tensioning System Bar,

Our Prestressing thread bar system Grade 930/1080 had been used on several bridges in India,Thailand and Colombia

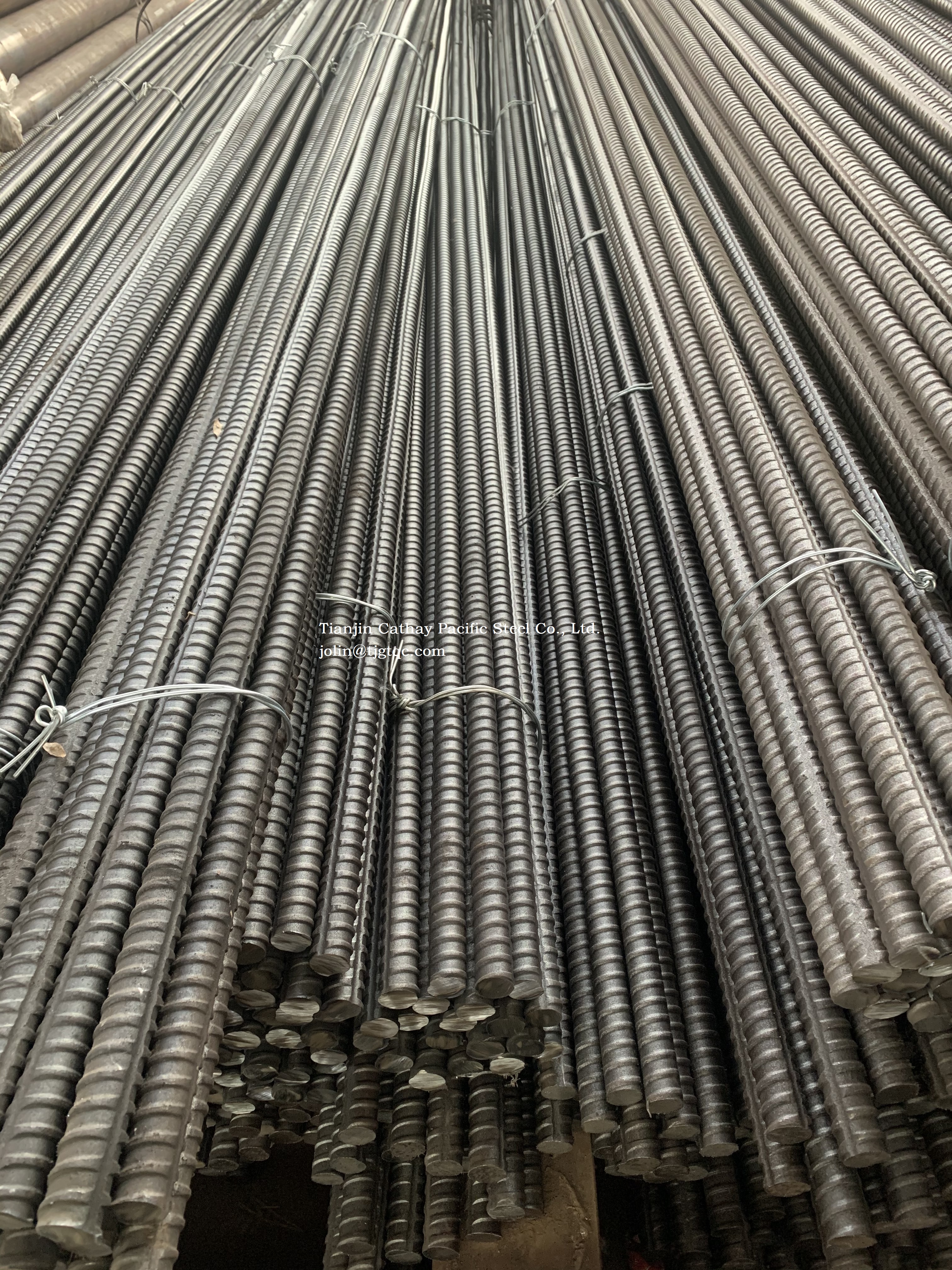

Stock for Post Tensioning Screw Thread Steel Bar

Lead time can be within 7 days.

Tianjin Guotai Gancheng Steel Co., LTD. Main business: fine rolled rebar and supporting anchor (fine rolled nut, fine rolled gasket, fine rolled connector, screw bar), 15.2 steel strand and other steel.

Introduce: Long term supply of Φ15, Φ20, Φ25, Φ28, Φ32, Φ36, Φ40, Φ42, Φ50, Φ63.5, Φ75 (mm) fine rolled screw steel.

The threaded bar for prestressed concrete (also called fine rolled threaded bar) is a straight bar with large diameter, high strength and high dimensional precision rolled on the whole bar with discontinuous external thread. The steel bar at any section can be screwed on a connector with internal thread for connection or screwed on threaded nuts for anchorage.

Product detail pictures:

Related Product Guide:

owing to excellent assistance, a variety of high quality products and solutions, aggressive costs and efficient delivery, we take pleasure in an excellent popularity amongst our customers. We are an energetic business with wide market for OEM Manufacturer Hot Rolled Bar - Post Tensioning Screw Thread Steel Bar – Cathay, The product will supply to all over the world, such as: Buenos Aires, Cancun, Madras, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

| Nominal Diameter | Diameter | H | B | L | Nominal Section | Nominal Weight | |

| Dv | Dh | ||||||

| mm | mm | mm | mm | mm | mm | mm2 | kg/m |

| 15 | 15 | 15 | 1.0 | 4.5 | 10 | 176 | 1.47 |

| 18 | 18 | 18 | 1.0 | 4.0 | 10 | 254.5 | 2.11 |

| 20 | 20 | 20 | 1.3 | 4.8 | 10 | 314 | 2.47 |

| 25 | 25 | 25 | 1.6 | 6.0 | 12 | 490.9 | 4.10 |

| 32 | 32 | 32 | 2.0 | 7.0 | 16 | 804.2 | 6.65 |

| 36 | 36 | 36 | 2.5 | 8.0 | 18 | 1018 | 8.41 |

| 40 | 40 | 40 | 3.0 | 8.0 | 20 | 1256.6 | 10.34 |

| 50 | 50 | 50 | 3.0 | 9.0 | 24 | 1963.5 | 16.28 |

| 60 | 60 | 60 | 3.0 | 10.0 | 22 | 2827 | 23.26 |

| 63.5 | 63 | 63.5 | 3.0 | 12.0 | 22 | 3167 | 26.20 |

| 65 | 65 | 65 | 3.0 | 12.0 | 22 | 3318 | 27.470 |

| 70 | 70 | 70 | 3.0 | 12.0 | 22 | 3848 | 31.8 |

| 75 | 75 | 75 | 3.0 | 12.0 | 22 | 4418 | 36.9 |

| Grade500/630 | NominalDia. | CrossSection | YieldStrength | TensileStrength | YieldLoad | UltimateLoad | Elongation | NominalWeight |

| mm | mm2 | >=Mpa | >=Mpa | KN | KN | A/% | KG/m | |

| 20 | 314 | 500 | 630 | 157 | 198 | 10 | 2.47 | |

| 25 | 491 | 500 | 630 | 246 | 309 | 10 | 4.1 | |

| 28 | 615 | 500 | 630 | 308 | 387 | 10 | 4.83 |

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,