Manufacturer of High Tensile Steel Screw Thread Bars - Prestressing Steel In Prestressed Concrete or Steel Bar – Cathay Detail:

Prestressing Steel In Prestressed Concrete or Steel Bar

A threaded bar can be used as a ground anchor by drilling a hole into the ground and inserting the bar deep enough to provide sufficient stability for whatever is being anchored. This could be anything from a small tent or canopy to a large sign or billboard. The bar is typically secured in place with concrete, soil, or other materials that provide enough friction to prevent it from being pulled out of the ground by force. Depending on the weight and size of the structure being anchored, multiple bars may be needed to ensure the necessary strength and stability.

System Description:

The screw thread steel bars for the prestressing of concrete manufactured by our company is a high tensile alloy steel bar which features a coarse right-hand thread over its full length and available in two standard lengths, namely 9m and 12m,yet,special length is negotiable based on user’s demand subject to the maximum length of 18m.

The screw thread steel bar

Fully Threaded Bar - can be cut and coupled at any point.

Low Relaxation Steel - minimum relaxation during service life.

Prestressing Grade Steel - high strength offers weight savings and reduced working diameters.

| Grade | PSB500,PSB830,PSB930,PSB1080 |

| Diameter | 15mm,0mm,25mm,32mm,36mm,40mm,50mm |

Applications:

Our thread bar systems are used for connections, formwork and anchorages and have been installed in large-scale construction projects worldwide. Whether for building, underground, bridge or road construction, tunnelling or mining.

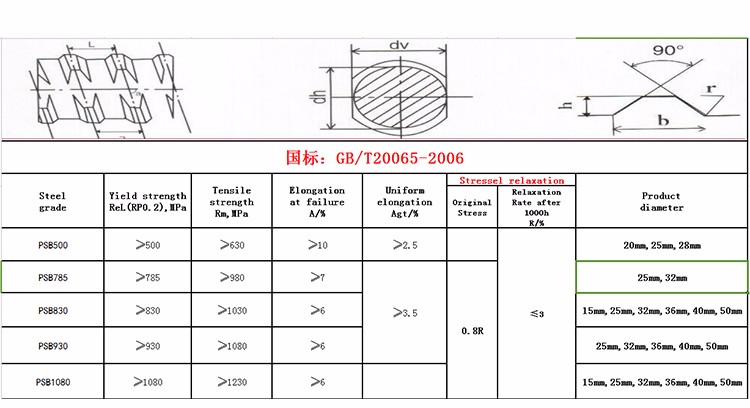

Specification

rebar prices steel rebar PS500 screw-thread steel Hot rolled ribbed steel bar G500 standard

1. Different grade: 500/630, 830/1030, 930/1080, 1080/1230

2. Diameter range: 15mm, 20mm, 25mm, 32mm, 36mm, 40mm, 50mm, 63.5mm, 75mm

3. Usage: rock bolt, soil nailing, tunneling, mining, bridge construction

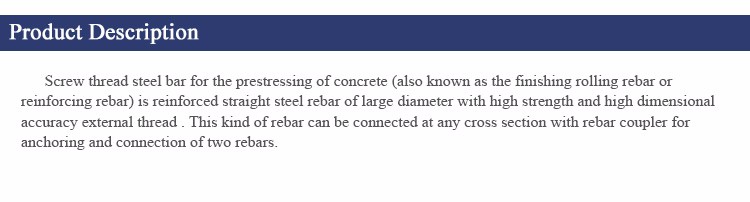

Product Description

Production Flow

laboratory

Certifications

Company Information

Advantages

Packaging & Shipping why is so good butiful ,I’m is very haypp. Tome is so so,Threaded Steel Bar.

Stock with fastest dlievery

Contact Information

Wendy Lee

Tianjin Cathay Pacific Steel Co.,Ltd

Email: tjgtqc@tjgtqc.com

WhatsApp: 0086-176 1227 5091

WANT TO WORK WITH US?

Product detail pictures:

Related Product Guide:

Well-run equipment, specialist income crew, and better after-sales services; We're also a unified major family, anyone stay with the organization value "unification, determination, tolerance" for Manufacturer of High Tensile Steel Screw Thread Bars - Prestressing Steel In Prestressed Concrete or Steel Bar – Cathay, The product will supply to all over the world, such as: New Zealand, Nicaragua, Colombia, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

| Nominal Diameter | Diameter | H | B | L | Nominal Section | Nominal Weight | |

| Dv | Dh | ||||||

| mm | mm | mm | mm | mm | mm | mm2 | kg/m |

| 15 | 15 | 15 | 1.0 | 4.5 | 10 | 176 | 1.47 |

| 18 | 18 | 18 | 1.0 | 4.0 | 10 | 254.5 | 2.11 |

| 20 | 20 | 20 | 1.3 | 4.8 | 10 | 314 | 2.47 |

| 25 | 25 | 25 | 1.6 | 6.0 | 12 | 490.9 | 4.10 |

| 32 | 32 | 32 | 2.0 | 7.0 | 16 | 804.2 | 6.65 |

| 36 | 36 | 36 | 2.5 | 8.0 | 18 | 1018 | 8.41 |

| 40 | 40 | 40 | 3.0 | 8.0 | 20 | 1256.6 | 10.34 |

| 50 | 50 | 50 | 3.0 | 9.0 | 24 | 1963.5 | 16.28 |

| 60 | 60 | 60 | 3.0 | 10.0 | 22 | 2827 | 23.26 |

| 63.5 | 63 | 63.5 | 3.0 | 12.0 | 22 | 3167 | 26.20 |

| 65 | 65 | 65 | 3.0 | 12.0 | 22 | 3318 | 27.470 |

| 70 | 70 | 70 | 3.0 | 12.0 | 22 | 3848 | 31.8 |

| 75 | 75 | 75 | 3.0 | 12.0 | 22 | 4418 | 36.9 |

| Grade500/630 | NominalDia. | CrossSection | YieldStrength | TensileStrength | YieldLoad | UltimateLoad | Elongation | NominalWeight |

| mm | mm2 | >=Mpa | >=Mpa | KN | KN | A/% | KG/m | |

| 20 | 314 | 500 | 630 | 157 | 198 | 10 | 2.47 | |

| 25 | 491 | 500 | 630 | 246 | 309 | 10 | 4.1 | |

| 28 | 615 | 500 | 630 | 308 | 387 | 10 | 4.83 |

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

-

China OEM 25mm Scres-Thread Steel Bars - Fully...

-

Leading Manufacturer for Threaded Steel Bar - ...

-

18 Years Factory Threadbar - Fully Threaded St...

-

Chinese Professional Post Tensioning Screw Thre...

-

China Gold Supplier for Concrete Reinforced Ste...

-

Good Wholesale Vendors Concrete Steel Bar - AS...