factory Outlets for Fully Thread Bar - Post Tensioning Tie Bars – Cathay Detail:

Post Tensioning Tie Bars

Grade Number of Post Tensioning Tie Bars

| Grade | Yield Strength | Tensile Strength |

| 500 | 500MPa | 630MPa |

| 830 | 830MPa | 1030MPa |

| 930 | 930MPa | 1080MPa |

| 1080 | 1080MPa | 1230MPa |

Application of Post Tensioning System Bar,

Our Prestressing thread bar system Grade 930/1080 had been used on several bridges in India,Thailand and Colombia

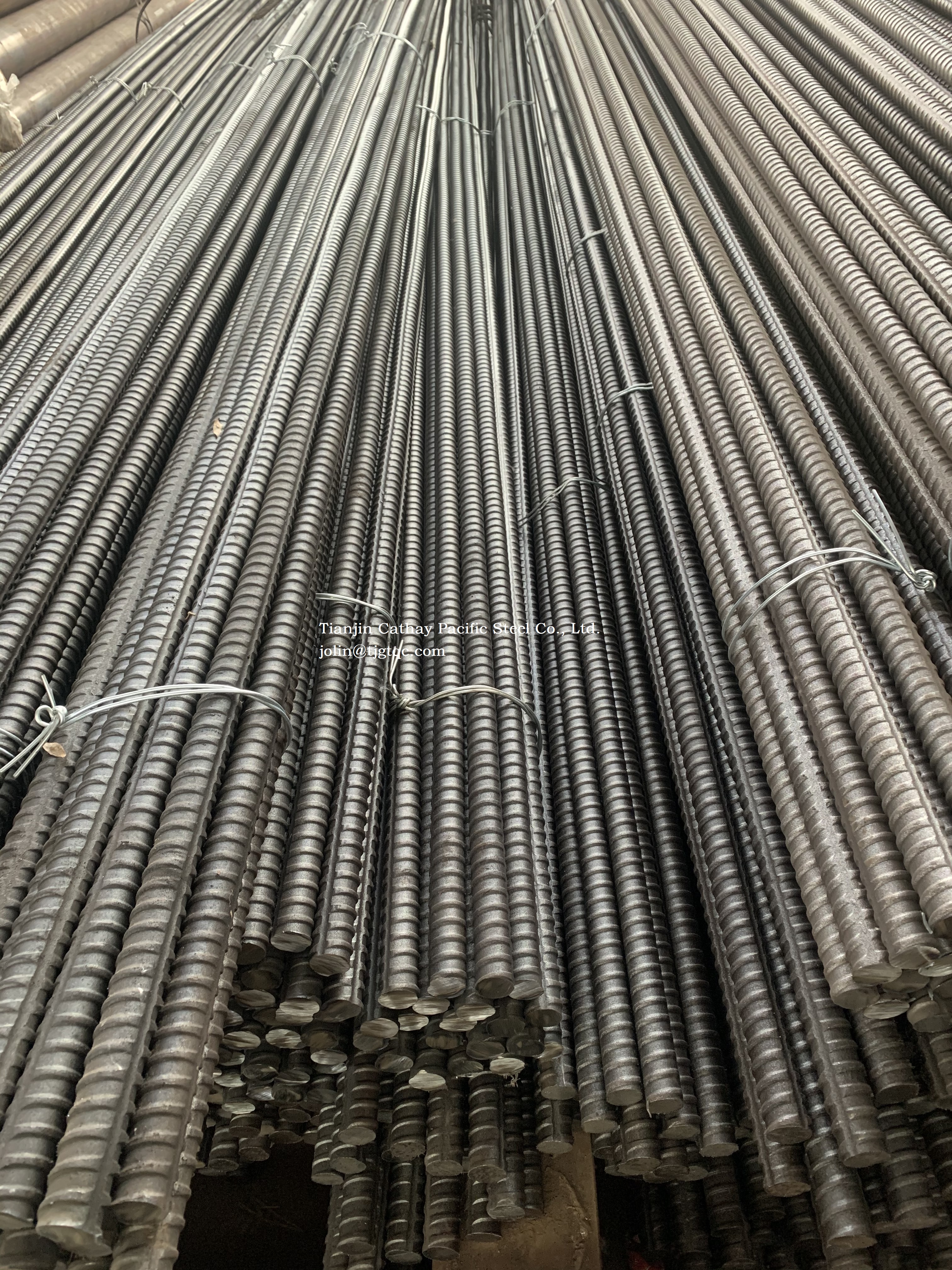

Stock for Post Tensioning Screw Thread Steel Bar

Lead time can be within 7 days.

Tianjin Guotai Gancheng Steel Co., LTD. Main business: fine rolled rebar and supporting anchor (fine rolled nut, fine rolled gasket, fine rolled connector, screw bar), 15.2 steel strand and other steel.

Introduce: Long term supply of Φ15, Φ20, Φ25, Φ28, Φ32, Φ36, Φ40, Φ42, Φ50, Φ63.5, Φ75 (mm) fine rolled screw steel.

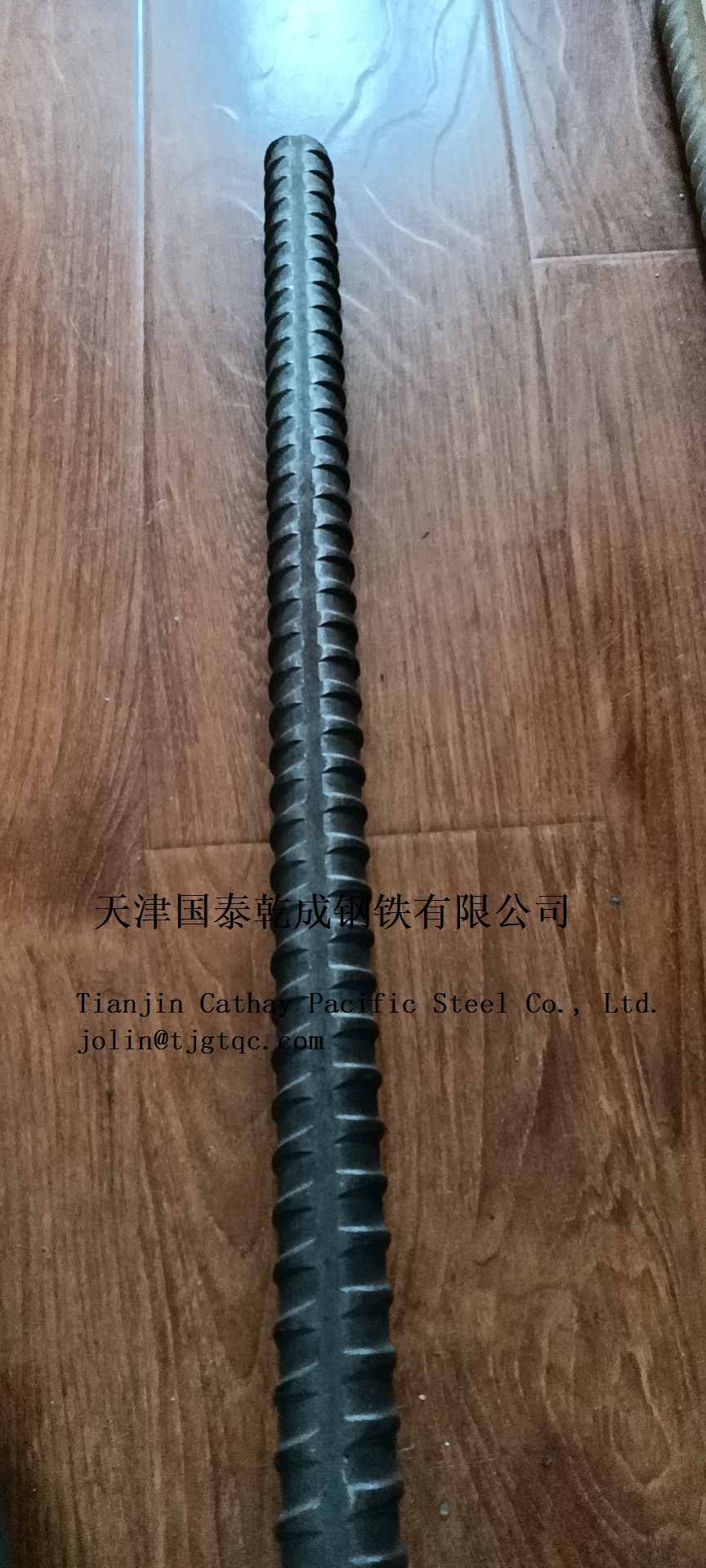

The threaded bar for prestressed concrete (also called fine rolled threaded bar) is a straight bar with large diameter, high strength and high dimensional precision rolled on the whole bar with discontinuous external thread. The steel bar at any section can be screwed on a connector with internal thread for connection or screwed on threaded nuts for anchorage.

Product detail pictures:

Related Product Guide:

The corporation upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will proceed to provide aged and new buyers from home and abroad whole-heatedly for factory Outlets for Fully Thread Bar - Post Tensioning Tie Bars – Cathay, The product will supply to all over the world, such as: Las Vegas, Wellington, Angola, We strongly believe that technology and service is our base today and quality will create our reliable walls of future. Only we have better and better quality , could we achieve our customers and ourselves, too. Welcome customers all over the word to contact us for getting further business and reliable relationships. We are always here working for your demands whenever you need.

| Nominal Diameter | Diameter | H | B | L | Nominal Section | Nominal Weight | |

| Dv | Dh | ||||||

| mm | mm | mm | mm | mm | mm | mm2 | kg/m |

| 15 | 15 | 15 | 1.0 | 4.5 | 10 | 176 | 1.47 |

| 18 | 18 | 18 | 1.0 | 4.0 | 10 | 254.5 | 2.11 |

| 20 | 20 | 20 | 1.3 | 4.8 | 10 | 314 | 2.47 |

| 25 | 25 | 25 | 1.6 | 6.0 | 12 | 490.9 | 4.10 |

| 32 | 32 | 32 | 2.0 | 7.0 | 16 | 804.2 | 6.65 |

| 36 | 36 | 36 | 2.5 | 8.0 | 18 | 1018 | 8.41 |

| 40 | 40 | 40 | 3.0 | 8.0 | 20 | 1256.6 | 10.34 |

| 50 | 50 | 50 | 3.0 | 9.0 | 24 | 1963.5 | 16.28 |

| 60 | 60 | 60 | 3.0 | 10.0 | 22 | 2827 | 23.26 |

| 63.5 | 63 | 63.5 | 3.0 | 12.0 | 22 | 3167 | 26.20 |

| 65 | 65 | 65 | 3.0 | 12.0 | 22 | 3318 | 27.470 |

| 70 | 70 | 70 | 3.0 | 12.0 | 22 | 3848 | 31.8 |

| 75 | 75 | 75 | 3.0 | 12.0 | 22 | 4418 | 36.9 |

| Grade500/630 | NominalDia. | CrossSection | YieldStrength | TensileStrength | YieldLoad | UltimateLoad | Elongation | NominalWeight |

| mm | mm2 | >=Mpa | >=Mpa | KN | KN | A/% | KG/m | |

| 20 | 314 | 500 | 630 | 157 | 198 | 10 | 2.47 | |

| 25 | 491 | 500 | 630 | 246 | 309 | 10 | 4.1 | |

| 28 | 615 | 500 | 630 | 308 | 387 | 10 | 4.83 |

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.

-

Top Suppliers High Tensile Strength Steel Bar -...

-

Good Wholesale Vendors Concrete Steel Bar - Fu...

-

Competitive Price for Asdo Tie Bars - Grade 50...

-

Manufacturing Companies for Threaded Steel Bars...

-

2019 Good Quality Fasteners And Nuts - Coupler...

-

OEM/ODM China Post Tension Wedge Post Tension B...